Do a dry test we called it as Dakongji. After the installation of brush machine, we add proper amount of lubricating oil in the brush machine, set up the lowest speed, with or without staple wire/flat wire (different tufting system) to run the brush machine for 24-72 hours or more. That is Dakongji.

How to choose round wire/flat wire according to different hole diameter?

Pulling force good or bad depends on the depth of tufting, wire is soft or hard, the length of wire, the diameter of wire, and the material of brush blocks. For the common brooms, it is appropriate that pulling force reaches 4 kg or more; For the toilet brush, it also needs 4 kg of pulling force or more;

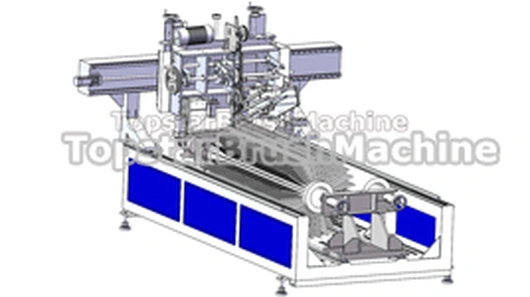

TOPSTAR Brush Machine needs to configure the air compressor, use air pressure to control color changing, fiber pressing, fiber pushing, fixture opening and closing, counter weight of table, and sometimes use to switch station and so on. Generally, TOPSTAR Brush Machine needs to configure

Should avoid damp, sun exposure, rain, excess dust, corrosive gases and explosive gases, strong electromagnetic interference, etc.

After open the wooden case, please check whether it is the product you buy; Check whether there is any damage to the goods during transit; Check product configuration list to confirm whether all parts are complete, and check for damage. If the product does not match, the lack of accessories or trans

Maintain a stable working voltage, prevent surge voltage from damage of electrical components. Working 8-12 hours per day. Please cut off the power when you don't use it for a long time. Put the machine on a smooth surface. Maintain the working environment of ventilation, to avoid high tempera

Punch filled (or Staple set) brushes are produced by stapling tufts of wire, is the most traditional brush making process. After punching the surface of the brush base, use a round wire system brush machine to tuft the bristles into the brush base one by one. The cost of the brush made by this process is

Flat wire tufting is a process suitable for thinner brush base. After punching or injection molding holes on the surface of the brush base, the flat wire system brush machine is used to tuft the bristles into the brush base one by one. Because the brush is a consumable item, the cost must be considered, and

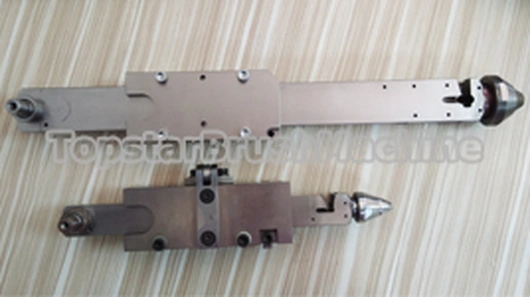

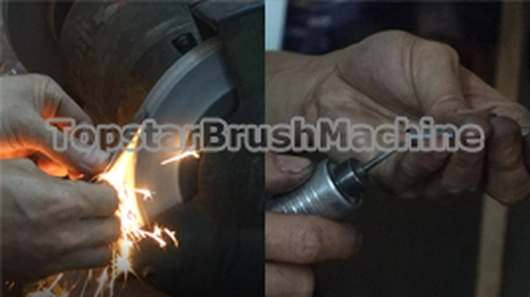

If tufting big diameter such as 3*2mm filament, the rear end of the opening hole of the picker and the upper end of the holder should be ground smooth; if filament diameter is small, such as 0.1mm, 0.15mm, the rear end of the opening hole of the picker and the upper end of the picker should be

The brush machine can tuft coconut fiber as long as the coconut fiber clean and tidy.

TOPSTAR’s high speed brush machine system has different stokes, such as 50mm, 130mm, 180mm 250mm and 300mm. That is, the length of bristle/filament outside hole can be 50mm, 130mm, 180mm, 250mm and 300mm. TOPSTAR’s small machine head system the maximum length of bristle/fiber out

TOPSTAR standard stroke high-speed brush machine the filament box for shortest total length of filament / bristle is 36mm, that is, 18mm after fold.

For now, the biggest hole that TOPSTAR brush machine tufts is 12mm. The tufting tools covers sizes of 3mm to 12mm.

Pulling force refers to how many kilograms of external force it takes to pull out the bristles from the hole after tufting. Generally, after we test tufting, we will use a pull meter device to test the pulling force.

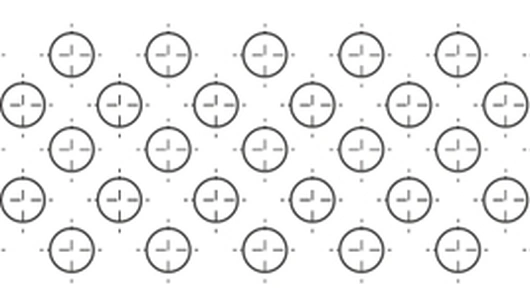

In order to prevent treading on the bristle, when programming an ordinary broom, we usually do not directly save the holes from the first hole to the last hole in the order of hole positions. Instead, after editing a certain hole, we will skip the next few adjacent holes, and program other holes, and then......

In order to make the tufting accessories cooperate with each other and better achieve the effect of tufting, it is generally necessary to polish certain positions of these accessories. For example, the end of the tufting needle should be ground into a groove, so that the staple wire is not easy to move out

The size of the tufting spare part is usually based on three data, the hole diameter, the diameter of the staple wire and the length of the staple wire after cutting. Taking the hole of 4.0 as an example, the standard size is 4.0-16*0.8mm, which means the aperture of 4.0, the 0.8 diameter of staple wire, and

Common hole patterns are straight, staggered, V-shaped and spiral. It can be a combination of the above four models, such as VV-shaped, staggered + V-shaped, etc. It is possible to do the grouping of all the above patterns. And, there are some more special patterns, such as arc shaped, trapezoid, and

Machine structure, system interfaces and their functions, interface operation instructions, circuit diagrams, common failure and solutions, safety instructions, and so on.