The strip brush is a U-shaped steel channel or strip (1), predominately zinc-coated or stainless steel (sometimes in brass or aluminium). A centre wire (2) made of the same material is placed in the U.

The filaments are placed between the strip and the wire. The two flaps of the strip are crimped together, forming the strip brush. The brush is then inserted into an extrusion or holder (4) for easier installation.

For some applications, the filaments are replaced or combined with rubber, neoprene, EPDM or PVC, etc. blades.

Rolled strip brush

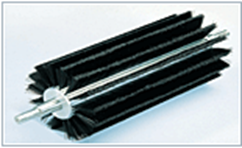

All strip brushes can be coiled on a shaft to make a tube brush. We machine the shaft for you. The strip brush number is defined by the dimensions and the filament. Strip brushes can be compressed, or coiled in a direction and a spacing width. This technique results in enhanced density that conventional processes do not give.

The density and spacing of the strip brush coiled onto the shaft brushes without leaving traces. The brush can be replaced, giving it an additional plus. It is best that the new brushed be coiled on the shaft in order to avoid losses in density during handling. Open face loops (without shaft) are only suitable for coils which are not subjected to significant forces and small brushes.

We tailor our brushes to fit your needs.

Helical strip brush on aluminium shaft

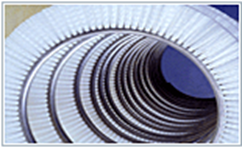

The brush is made of an extruded aluminium body with 30 slots for inserting No. 5 strip brushes (trim can be cut to desired length), centre rod, two end fixtures and 30 No. 5 strip brushes.

The centre rod, arbor holes on the flanges and the 30 No. 5 strip brushes can be custom made. Only the aluminium body cannot be changed.

Using a standard extruded aluminium body we can make a large number of combinations. Depending on the job, the shaft can be completely or partially covered with No. 5 strip brushes. Worn brushes can be changed by the user.

Notched strip brush

Dual notched strip made of zinc-covered or stainless steel accommodates all synthetic, natural and metal filaments. Outside winding with joinable loops.

Width 5.5 mm for small notches up to 70-80 mm; width 9.5 mm over 80 mm.

Filaments held tightly and cannot be pulled out.

Open face loops available.

Applications: surface treatment, rollers, washers, conveyor belts.

Fitted and shaped coiled brushes

This multi-purpose brush can be adapted to all your applications. These models can be made using all kind of strip brushes. We also manufacture prototypes and large series.

They can be used for many applications: vacuum cleaner brushes, machine tool housings, camshaft housing, car bodywork, etc.

Flexible strip brush

This brush's particular feature is that it is inserted into a U-shaped plastic channel reinforced by a metal wire.

Main advantages: easier to install: shaping, bending, etc. available in many lengths, reduces wastage smaller packaging means more savings and easier use and storage.