Technical Parameters:

Machine Model | DC8A | |

Axes | 8 | |

X-axis range (mm) | Max. 3000 *2 | |

Y-axis range (mm) | Max. 1500 | |

Z-axis range (º) | 360 *2 | |

A-axis range (º) | 90 | |

H-axis range (mm) | Max. 400 | |

Drilling | 1 | |

Filling | 1 | |

Tufting Type | Staple wire | |

Length of bristle outside hole (mm) | Min. 17 | Max. 130 |

Speed (r/min) | 300 | |

Fixtures | 3 | |

Hole diameter (mm) | Min. 3.0 | Max. 8.0 |

Total length of bristle (mm) | Min. 40 | Max. 270 |

Bristle diameter (mm) | Min. 0.07 | Max. 1.5 |

Color | 2 | |

Total power (kw) | 9 | |

Air consumption (mpa.) | 0.4 - 0.6 | |

Dimensions (L*W*H, cm) | Machine Body: 370 x 280 x 225 Electric Box: 45 x 65 x 147 | |

Weight (kg) | 2000 | |

Features:

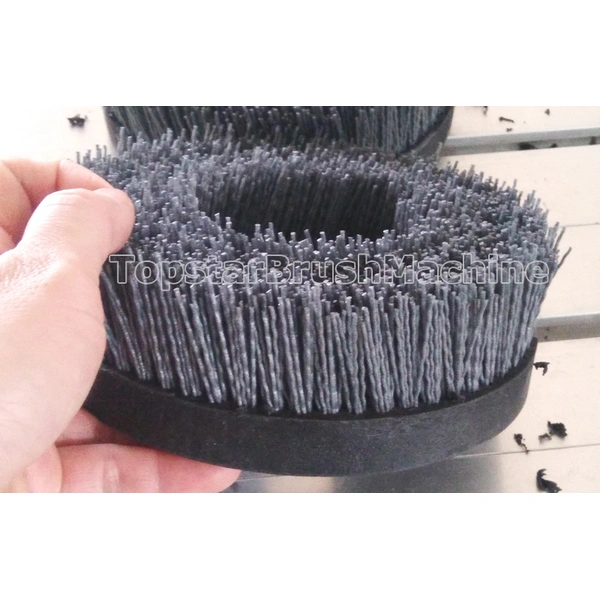

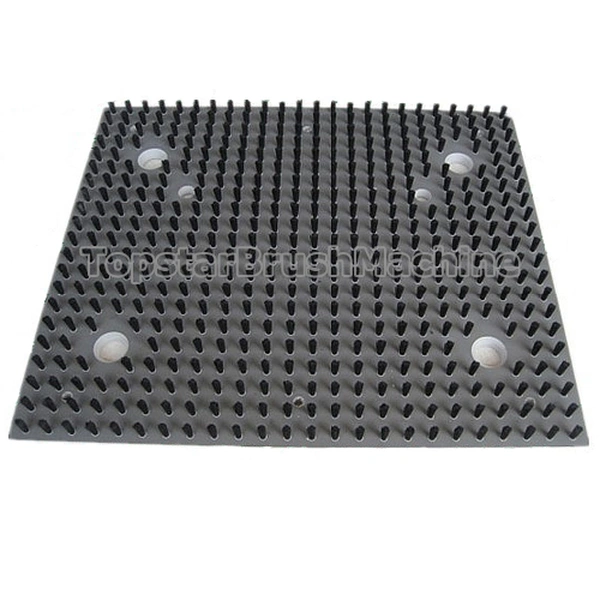

1. DC8A is a 3-in-1 integrated brush machine, which is able to produce disc brush / disk brush, cylinder brush / roller brush, lath brush / strip brush, board brush and other industrial technical brushes, such as fruit and vegetable cleaning brush, cow body brush, floor sweeper brush, floor scrubber brush, carpet / rug washing brush, polishing brush, grinder brush, grinding brush, etc.

2. It meets below standards of brush specifications:

1) Disc brush: outer diameter max. 700mm, filling angle 0-60º;

2) Roller brush: outer diameter max. 300mm, length of tube body max. 2500mm;

3) Plane brush: length max. 2000mm, width max. 1000mm;

4) Length of filament from the top of brush base: 130mm;

5) Hole diameter: 3.0-8.0mm.

3. The bristle conveyor has the advantages of high processing precision and good tightness, and can be used for filling fiber with a dimeter of 0.07mm, and the problem of bristle loss can be effectively reduced. Also, can fill 3*2mm PP big fiber, PA fiber, Steel wire, straight wire 3*0.6mm or corrugated / wave / crimped wire dia. < 0.7mm.

4. Adopt moveable gantry structure, stable and solid, safe and reliable.

5. Designed by 1 drilling and 1 tufting, support mixed drill and fill, drill fist then fill, synchronize drill and fill, drill only, fill only and other processing modes.

6. Adopt high-speed machine head system. Speed reaches 300r/m, 3-4 holes per second.

7. Single color and double colors are optional.

8. PLC and touch screen control system, multi-language version, such as Chinese, English and Spanish, easy to understand.

9. Software is with insert, division, offset, step hole, block move, block copy, and other functions. It is convenient and flexible, easy to program.

10. Can program different hole pattern, such as straight, staggered, V-shape, W- shape, U-shape / arc shape, spiral, trapezoidal, full circle type, avoiding space type, equal portion type, etc.

11. Unit of product data is in rows. The entire system can store 999 rows, each row can store 9999 holes, and each hole can expand 255 stepping holes. Divide into 32 product numbers, support external USB.

12. Tufting spare parts such as needle, concave die, convex die, etc. are standardized designs, and achieve multi-process finishing, beautiful and durable. Easy to repair and replace as well.

13. Use Italy brand brake motor, Delta or YASKAWA servo motor and driver, imported brand bearing, Schneider relay, and other good quality components.

14. Machine got CE approved.

Videos:

For more machine videos, please take a look at below links, thanks for your time.

https://youtu.be/CYaozB-FYqc

https://youtu.be/DDjFBEdoYF8

https://youtu.be/jkWweb8ePkI

https://youtu.be/2qLZ-0vV9mE

https://youtu.be/ZoSU9AoOb4g

https://youtu.be/7ENswfaSxUM

https://youtu.be/ZJPsvtT7DxY

https://youtu.be/pw7X2cZz_wk

https://youtu.be/3mKvxgcV6D4

https://youtu.be/uCKVbJ190eU

https://youtu.be/MBGJM924wU4

https://youtu.be/kZAXfWvAF7g

https://youtu.be/Ihz6Db1J6bM

https://youtu.be/iMNFD1iK41U

https://youtu.be/lt-uwoNmWQU

https://youtu.be/D-q6aPRibJ4

https://youtu.be/gNVYHJkCUtI

https://youtu.be/Ae99WuMm1BY