Technical Parameters:

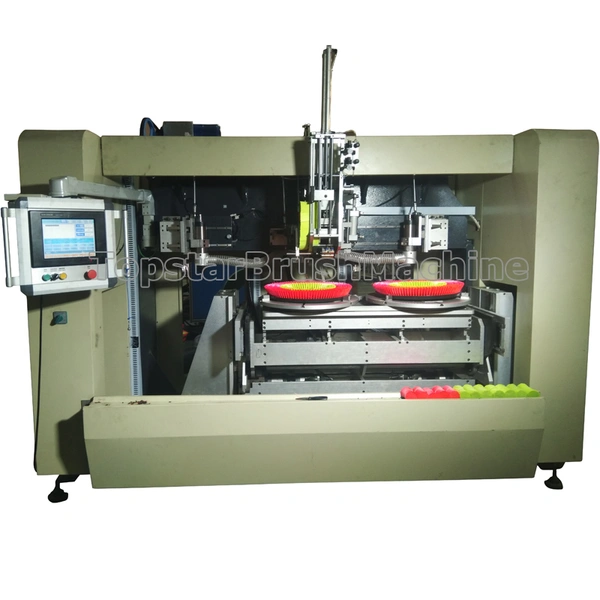

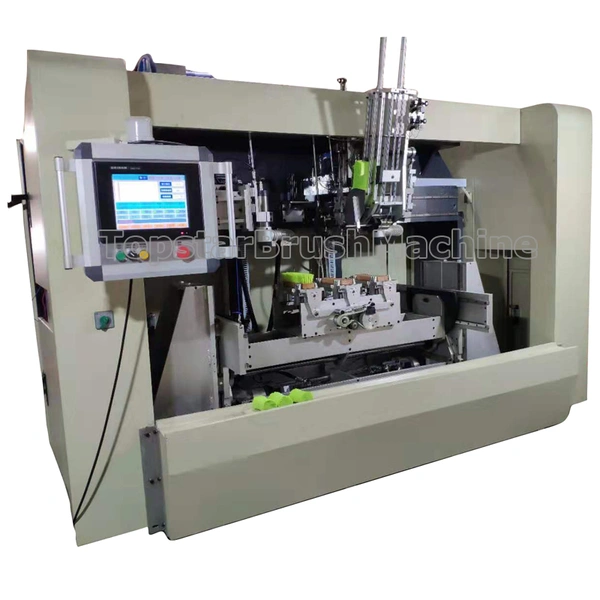

Machine Model | TG2 | |

Axes | 5 | |

X-axis range (mm) | Max. 510 | |

Y-axis range (mm) | Max. 510 | |

A-axis range (º) | 90 | |

B-axis range (º) | 360 | |

Z-axis range (mm) | Max. 300 | |

Drilling | 2 | |

Filling | 1 | |

Tufting Type | Staple wire | |

Length of bristle outside hole (mm) | Min. 17 | Max. 130 |

Speed (r/min) | 450 | |

Fixtures | 2 or 3 | |

Hole diameter (mm) | Min. 3.0 | Max. 8.0 |

Total length of bristle (mm) | Min. 40 | Max. 270 |

Bristle diameter (mm) | Min. 0.07 | Max. 1.5 |

Color | 2 | |

Total power (kw) | 11 | |

Air consumption (mpa.) | 0.4 - 0.6 | |

Dimensions (L*W*H, cm) | Machine Body: 276 x 146 x 245 Electric Box: 130 x 40 x 200 | |

Weight (kg) | 3000 | |

Features:

1. TG2 is a brush machine for many kinds of disc brushes, such as floor scrubber brush, floor sweeper brush, disc floor washing machine, carpet cleaning machine, rug washing machine, etc.

2. Can replace different platforms for other brushes, such as:

--- Flat platform for indoor broom, outdoor broom, car brush, scrubbing brush, dish brush, and other household brushes.

--- Round platform for round toilet brush, double hockey brush, ceiling duster brush, bottle brush, ball brush, etc.

--- Roller Platform for cylinder brush, roller brush, zigzag brush, etc.

3. Adopts high-speed machine head system. Speed reaches 450r/m, up to 7-8 holes per second.

4. Designed by 2 drillings and 1 filling, it’s flexible and equipped with a table 2 or 3 clamping stations, 2 or 3 fixtures, and works in continuous cycle, high efficiency.

5. PLC and touch screen control system, multi-language version, such as Chinese, English and Spanish, flexible and convenient operation.

6. Support synchronous drilling and tufting, drill only, tuft only, and other processing modes.

7. Software is with insert, division, array, offset, modify and other functions, flexible and convenient, easy to program.

8. Can save 1000 different brushes programs, and support external USB.

9. Single color and double colors are optional.

10. Tufting spare parts such as needle, concave die, convex die, etc. are standardized designs, and achieve multi-process finishing, beautiful and durable. Easy to repair and replace as well.

11. Automatic oil lubrication system, regularly and automatically lubricate the parts with high frequency operation, reduce wear and tear.

12. Use Italy brand brake motor, Delta or YASKAWA servo motor and driver, imported brand bearing, Schneider relay, and other good quality components.

13. Machine got CE approved.

Videos:

For more machine videos, please take a look at below links, thanks for your time.

https://youtu.be/aV80eljZGc4

https://youtu.be/n_ZmDS_ve94

https://youtu.be/8Yx8AuxNx9s

https://youtu.be/cE_w1BvWS84

https://youtu.be/RbwzrHkIFZA

https://youtu.be/x4SfV4q8HgU

https://youtu.be/JBDxJ19V7Mc

https://youtu.be/b1krt5YQSE8

https://youtu.be/isa4hPMvcHQ

https://youtu.be/nrW2h3FVn_4

https://youtu.be/-vv5ETYW2Sk